1.What is a mini excavator?

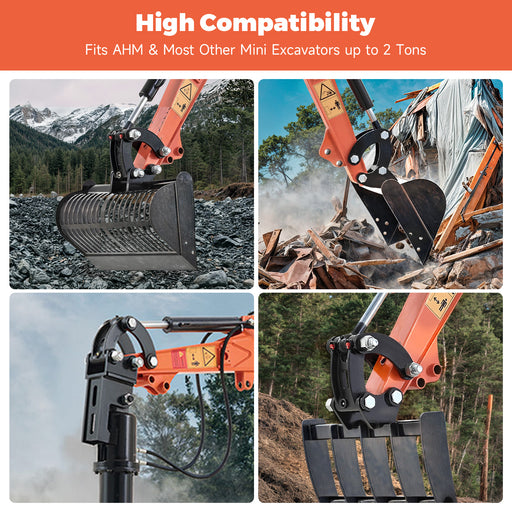

A mini excavator, also known as a compact excavator, is a small, versatile machine used primarily for digging in a variety of settings, including construction, landscaping, and utility work. Unlike larger excavators, mini excavators have a compact footprint and are lightweight enough to be transported easily. They typically feature a standard backfill blade and can be equipped with various attachments, making them ideal for tasks in tight spaces where larger equipment would not fit or would be too disruptive.

2.How much does a mini excavator weigh?

Mini excavators come in various sizes, which correspond to their weight. Typically, their weight ranges from approximately 2,000 pounds (about 1 ton) to 18,000 pounds (about 8 tons). The weight of a mini excavator is an important factor to consider, especially when it comes to transportation and the type of terrain on which it can be used without causing damage to the ground.

3.How wide is a mini excavator?

The width of a mini excavator is crucial for determining if it can fit into restricted or narrow areas. Widths range from about 3.5 feet (1.06 meters) to 6 feet (1.83 meters). This dimension helps to ensure that the excavator can access and operate in confined spaces, such as between buildings or inside enclosed yards.

4.How deep can a mini excavator dig?

The digging depth of a mini excavator depends on the size of the machine and the type of boom configuration it uses. Smaller models may have a maximum digging depth of approximately 5 feet (1.5 meters), whereas larger mini excavators might reach depths up to 12 feet (about 3.66 meters) or more. Choosing the right size excavator for your project is essential to ensure it can handle the required digging tasks.

5.How much can a mini excavator lift?

Lifting capacity in mini excavators is determined by the size and design of the machine. Generally, they can lift loads ranging from 500 pounds (227 kilograms) to 4,000 pounds (about 1,814 kilograms). However, it's important to consult the manufacturer's guidelines for specific lift capacity limits to avoid overloading the machine, which can be unsafe and may lead to tipping.

6.How to operate a mini excavator?

Operating a mini excavator involves several key steps:

Pre-Operation Checks: Ensure the machine is in good working order by checking fluid levels, the condition of the tracks or wheels, and the general state of the excavator's attachments and cables.

Safety Measures: Before starting, clear the area of bystanders and obstacles, and plan your digging route.

Starting Up: Engage the ignition and let the engine warm up for a few minutes.

Maneuvering: Use the joystick controls to operate the arm, boom, bucket, and rotate the cab. The other set of controls typically operates the machine’s movement and the blade.

Digging and Lifting: Follow safe digging practices, keeping the machine balanced and stable during operations.

7.How to load a mini excavator on a trailer?

Loading a mini excavator onto a trailer requires careful preparation to ensure safety:

Align the Ramp: Position the ramp so it's securely attached to the trailer and aligned with the tracks of the excavator.

Drive Slowly: Slowly drive the excavator up the ramp, keeping movements smooth to avoid tipping.

Secure the Excavator: Once on the trailer, lower all hydraulic arms and the blade, turn off the machine, and use chains or straps to secure the excavator to the trailer. Ensure it's stable and won’t shift during transport.

8.What size mini excavator do I need?

Choosing the right size of mini excavator depends on several factors:

Job Requirements: Assess the scope of the project, including the depth and width of the digging required.

Space Constraints: Consider the size of the work area and access points. Smaller models are better suited for tight spaces.

Lift Capacity: Ensure the machine’s lift capacity meets the needs of the job for moving materials or other specific tasks.

Transportation and Storage: Larger models require more robust transportation and storage solutions.